Cabrillo College is responding to the shortage of face masks for doctors and nurses created by the Coronavirus COVID-19 pandemic — gearing up to produce the protective equipment using 3D printers.

Payson McNett, Cabrillo College art studio instructor and director of digital fabrication, came up with the idea to use the MakerSpace on campus.

Matt Wetstein, Cabrillo College Superintendent/President, deemed the work essential so Makerspace, which has a variety of 3D printers, is open while the rest of campus is closed to slow spread of the coronavirus, which has infected 104,000 people in the U.S. and killed 1,700, including 78 in California. Santa Cruz County has 34 cases.

Last week, doctors started a campaign on Twitter #getmePPE, referring to personal protective equipment worn to protect them from infection. They say there aren’t enough masks and face shields. The California Nurses Association/National Nurses United has the same complaint.

McNett researched the best options for 3D printed masks and face shields, which led him to the Billings Clinic Foundation in Montana.

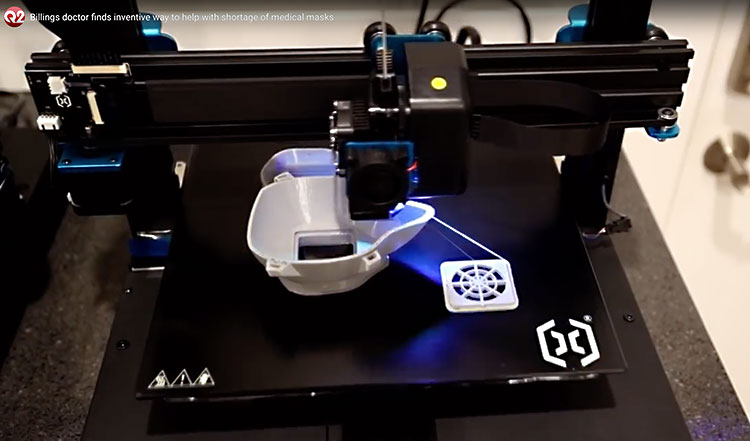

There, Dr. Dusty Richardson, a neurosurgeon, in collaboration with Spencer Zaugg, a dentist, and his son Colton, created and posted designs for durable, reusable plastic masks that can be created using 3D printer technology.

There, Dr. Dusty Richardson, a neurosurgeon, in collaboration with Spencer Zaugg, a dentist, and his son Colton, created and posted designs for durable, reusable plastic masks that can be created using 3D printer technology.

According to their website, they are working to “activate every 3D printer in our community to create these masks.”

McNett is answering that call.

The Billings 3D printed mask has a snap-in section for medical grade filtration materials that can be changed when needed.

McNett is using HEPA vacuum filters, and is working on providing links on the Cabrillo Makerspace website with information and testing and efficacy of other more readily available materials.

McNett got face shield designs from Joseph Prusa, a 3D printer designer and manufacturer.

“I’m ready to go into production of these items and have a good stockpile of printer filament and Poly Carbonate to keep me busy,” said McNett.

“I’m ready to go into production of these items and have a good stockpile of printer filament and Poly Carbonate to keep me busy,” said McNett.

Once masks are prototyped, McNett expects to create rubber “gang molds,” which will enable him to ramp up production from 100 masks per day to potentially thousands per day, so long as materials are still available.

He encourages tinkerers in the community to give him feedback.

“If you would like to send me your prototypes, I would love to take a look at the files for you and help answer any design questions you might have,” said McNett. “I’m totally open to different or better designs, I just haven’t found them yet.”

For prototypes or help with designs, contact Payson McNett at [email protected].

To make a donation for supplies, give through the Cabrillo College Foundation at foundation.cabrillo.edu and indicate the donations are for the Digital Fabrication Program.